Technology News

Hands-On ‘mini’ Textiles During Remote Learning

…and so Production goes on. Remote learning is not a barrier to learning. While many assume that practical or ‘hands-on’ subjects can’t continue during remote learning and skills are lost or missed, this is quite untrue. All that is required is a shift to flexible thinking. As the saying goes, ‘there are many ways to skin a cat’.

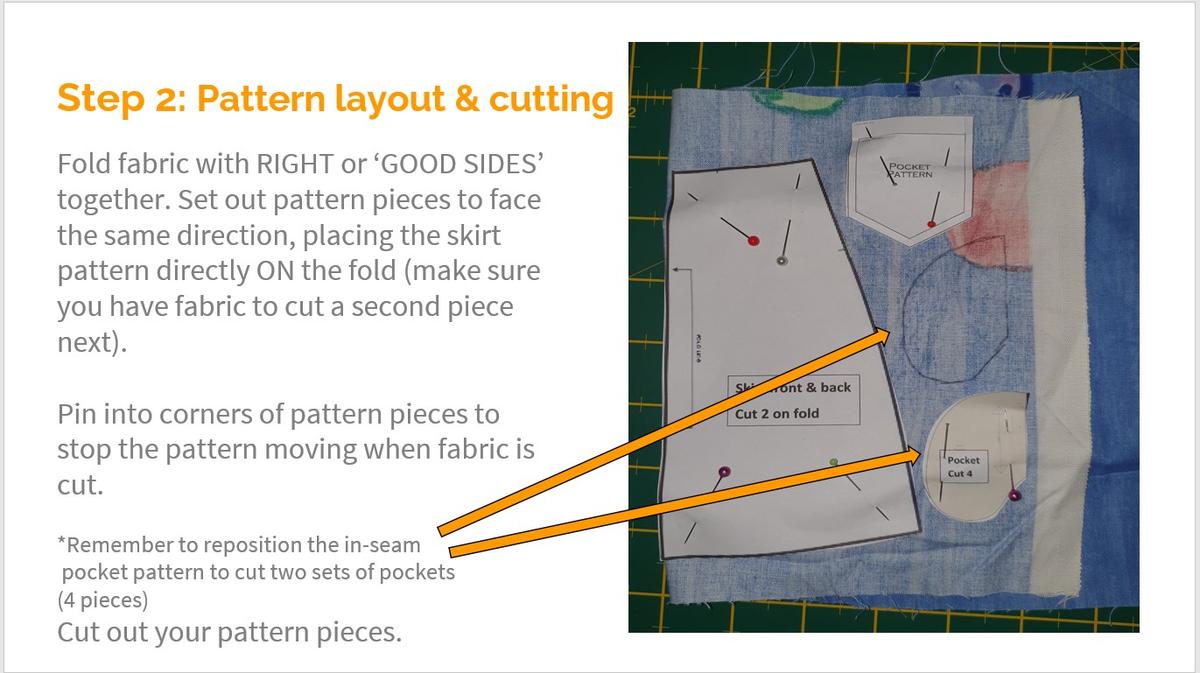

As one of the curriculum concepts in any Technology subject includes sustainability in resource use, the remote learning experience provides a stronger experience as students are challenged during upcycling tasks to reinvent their thinking about what ‘materials’ may extend to. In the case of Textiles, our ‘fabrics’ were not those ordered through a ‘click-and-collect’ store, but everyday items we were challenged to use and give new life to. In Year 9 Fast Fashion, our woven fabric was sourced from items such as disused men’s handkerchiefs, tea towels, placemats, curtains, outgrown clothing and hand-me-downs. Our task was to make a mini ‘scale-model’ Fast Fashion skirt so that we could learn the stages of garment construction from pattern layout and cutting through to completion of a finished garment. To achieve this, simple tools of a hand sewing needle and a small amount of thread were combined with a scaled-down pattern and a Google slides tutorial demonstrating each step in construction.

To replicate stitches made by a sewing machine, students completed hand-sewn seams using backstitch which they were able to self-teach by following a video provided to them. Thinking creatively, the elastic needed for an elasticised waistband was sourced from an elastic band used to bundle the mail, a hair tie, ear elastic from an unused, disposable face mask, or thin elastic retrieved from the cuffs of pyjama tops/bottoms and sunhat straps – you get the idea.

Some of the construction skills learnt through this exercise include ‘fabric’ selection, pattern layout and cutting out, seam construction, garment assembly, elastic casings, in-seam pockets, patch pocket assembly and application, rolled hem. All this in a garment size no bigger than your hand!

Below is an image of the working model constructed for the making of the student tutorial (this one is made from curtain off-cut)

Whilst the Yr 9 students were involved in this project, the Year 10’s worked similarly on a scaled down Hoodie which is made from a stretch fabric. Where do you get stretch fabric when the brief is to upcycle and use what is already available to us? Well…easy really. A pair of thinning or outgrown socks can be cut open from toe through heel to top, to provide a sheet of ‘fabric’. Or a disused T-shirt or singlet can become fabric. Shortening the legs on a pair of track pants can provide a strip of fabric. All it takes is a few starter ideas and a little imagination and other ideas quickly emerge. This one is made from the cut-offs when a pair of track pants were shortened:

The finished size of this mini-Hoodie was 15cm from hood to hem – perfect for a younger siblings Ken or Barbie.

Annette Marschner

Textiles teacher - Cranbourne Campus