STEM: Innovator's Hub

An Experience-Based Learning Program

STEM: Innovator's Hub

An Experience-Based Learning Program

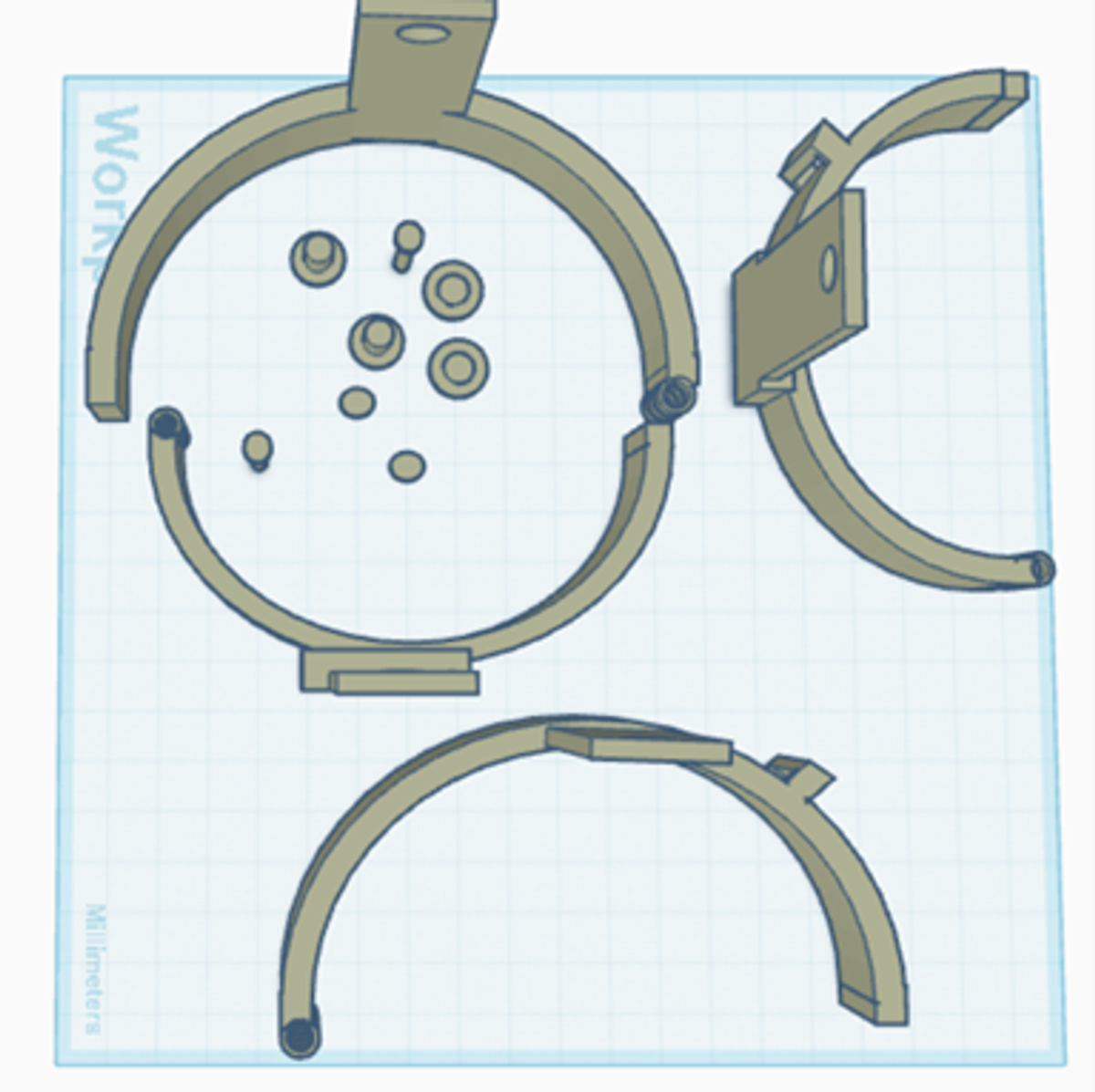

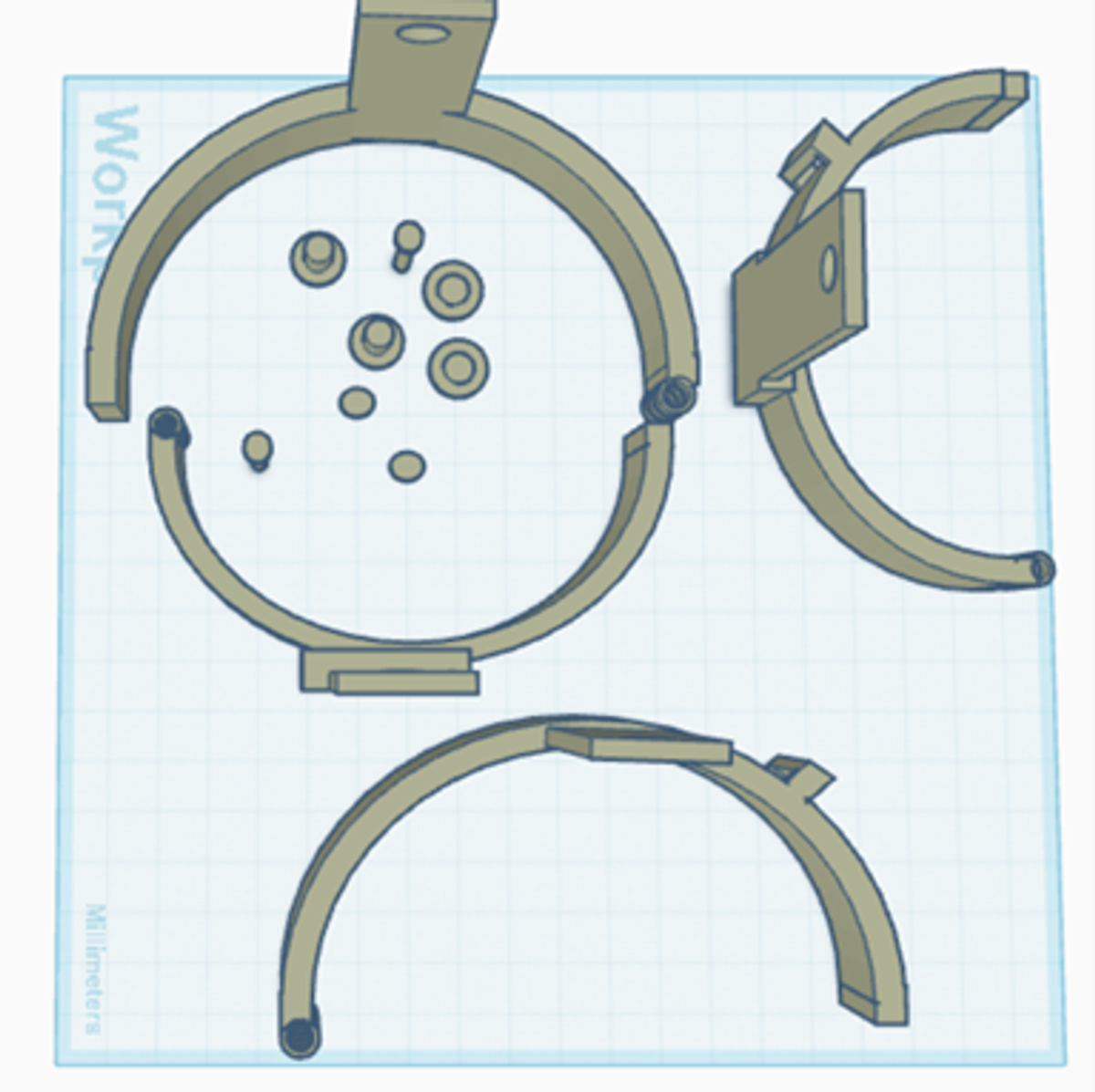

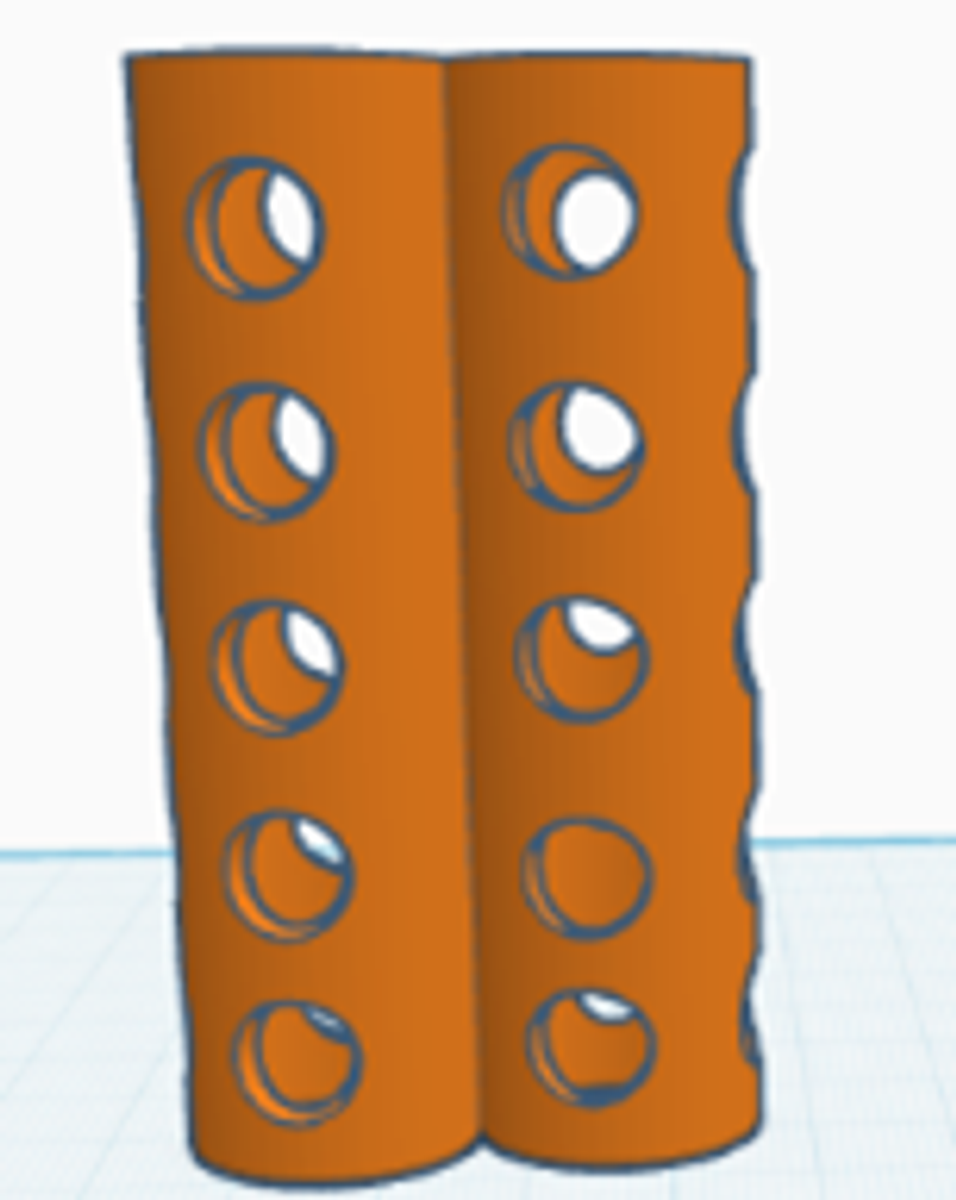

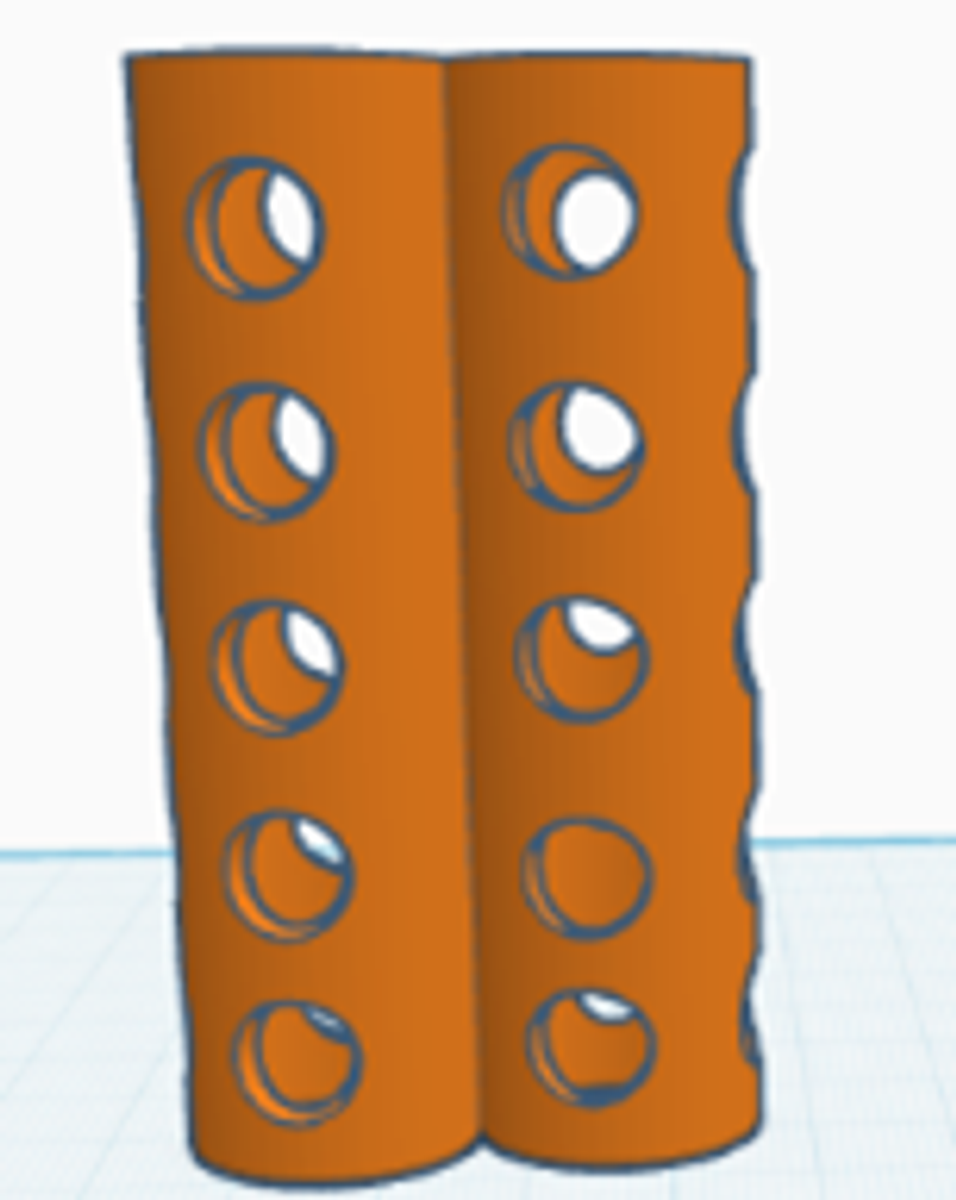

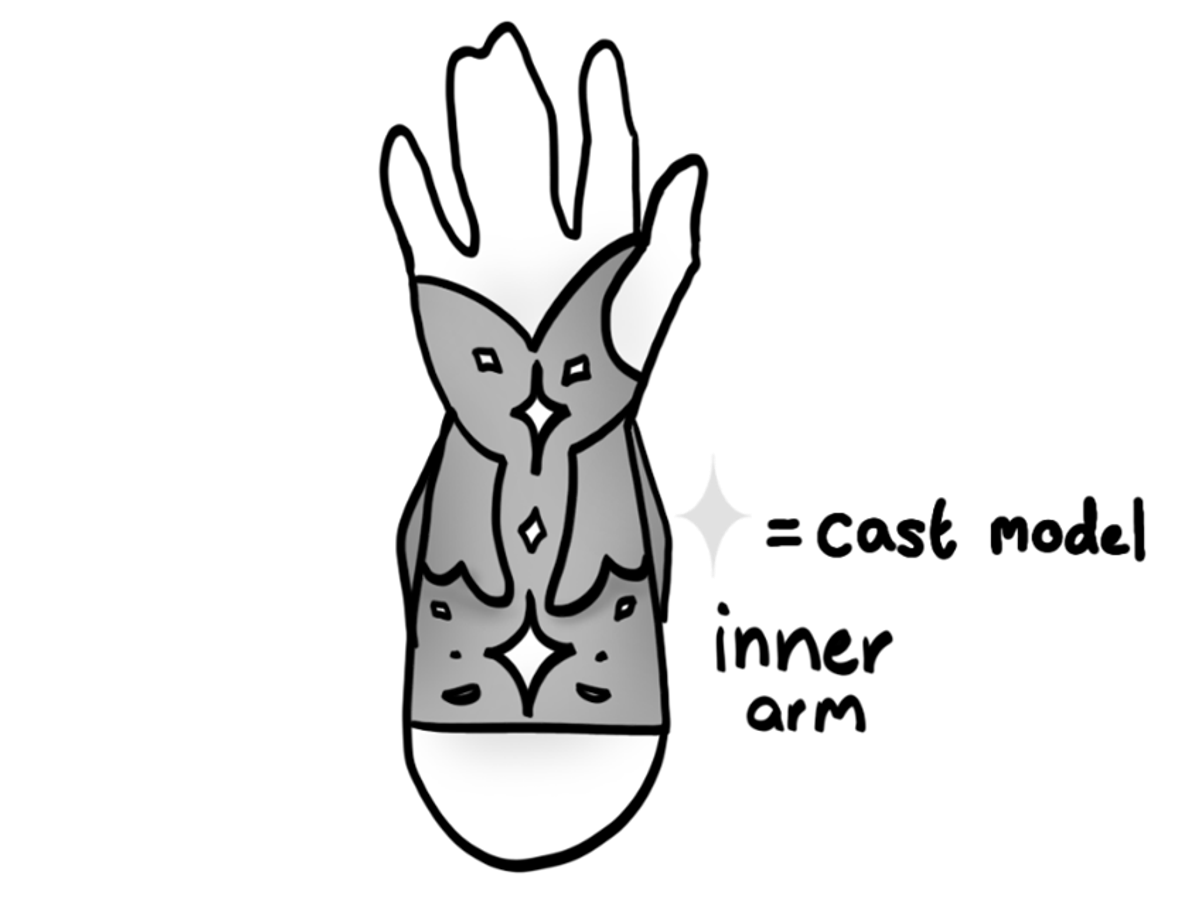

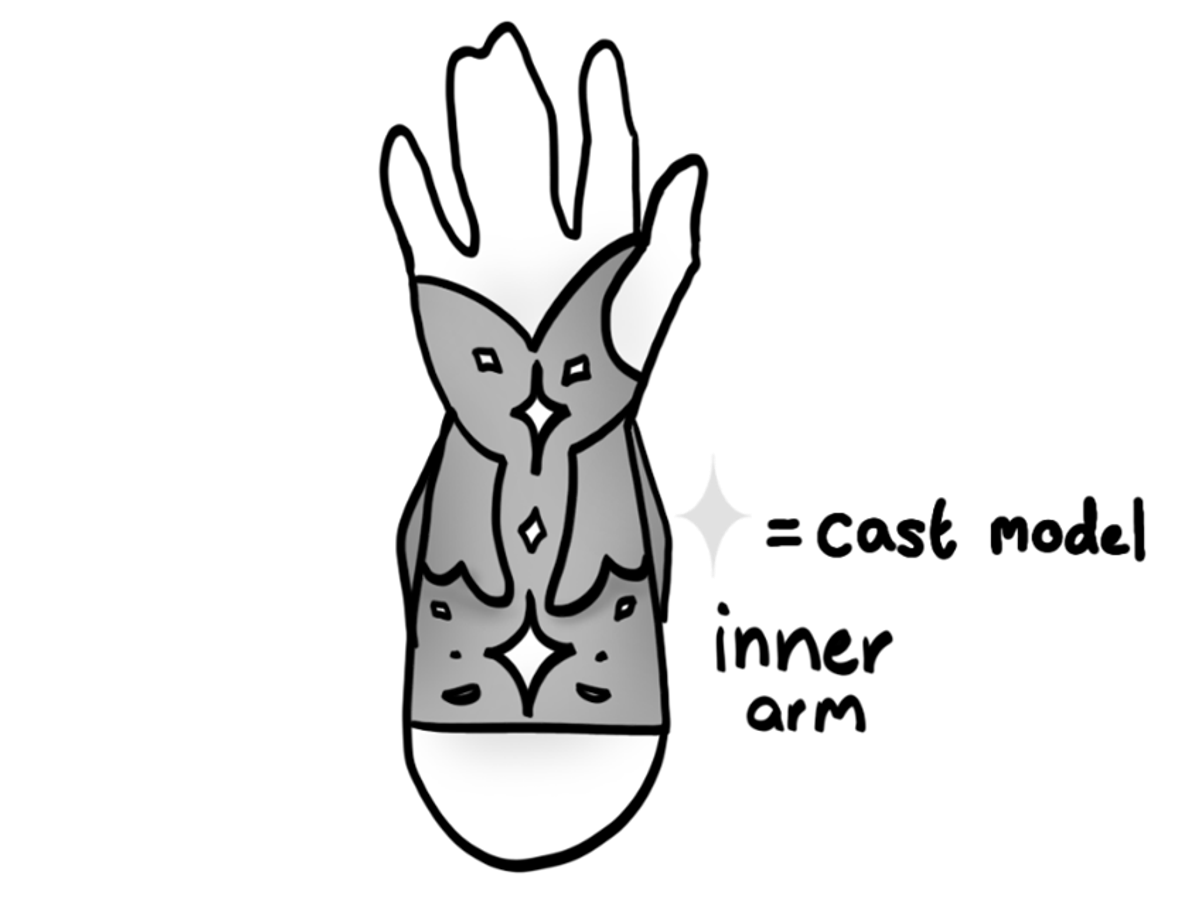

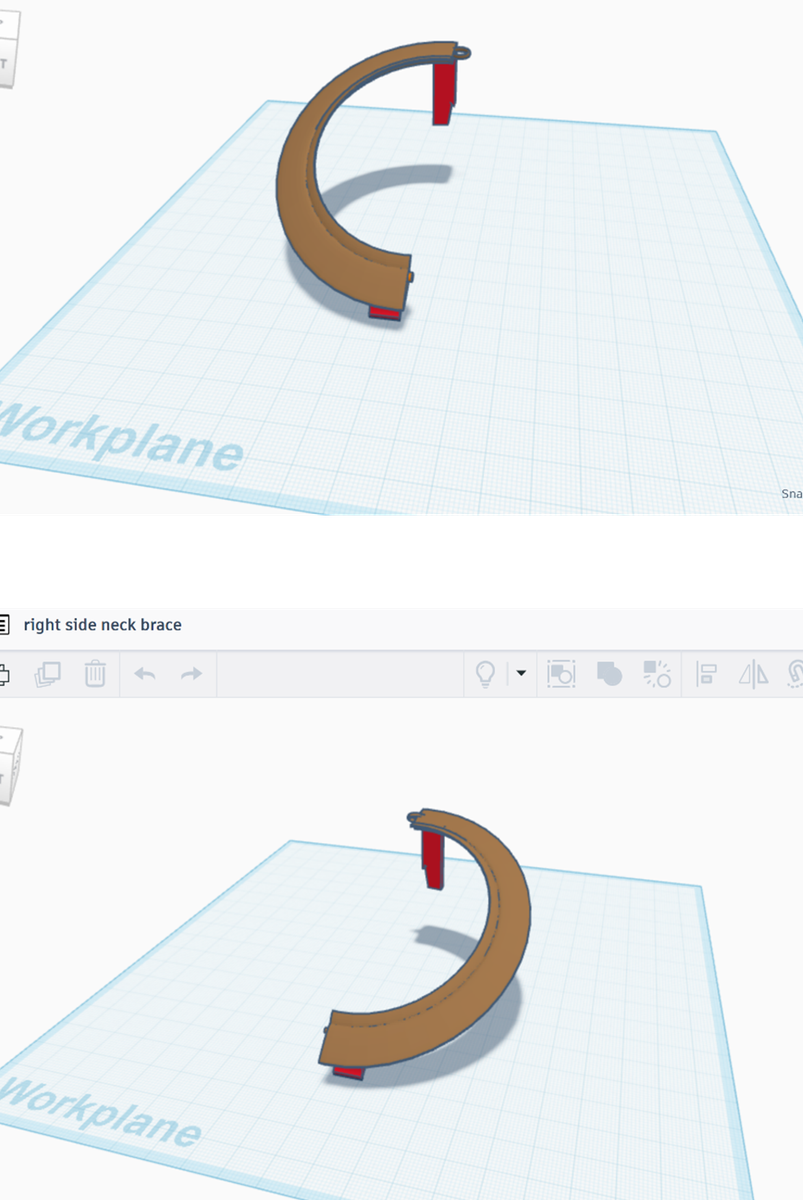

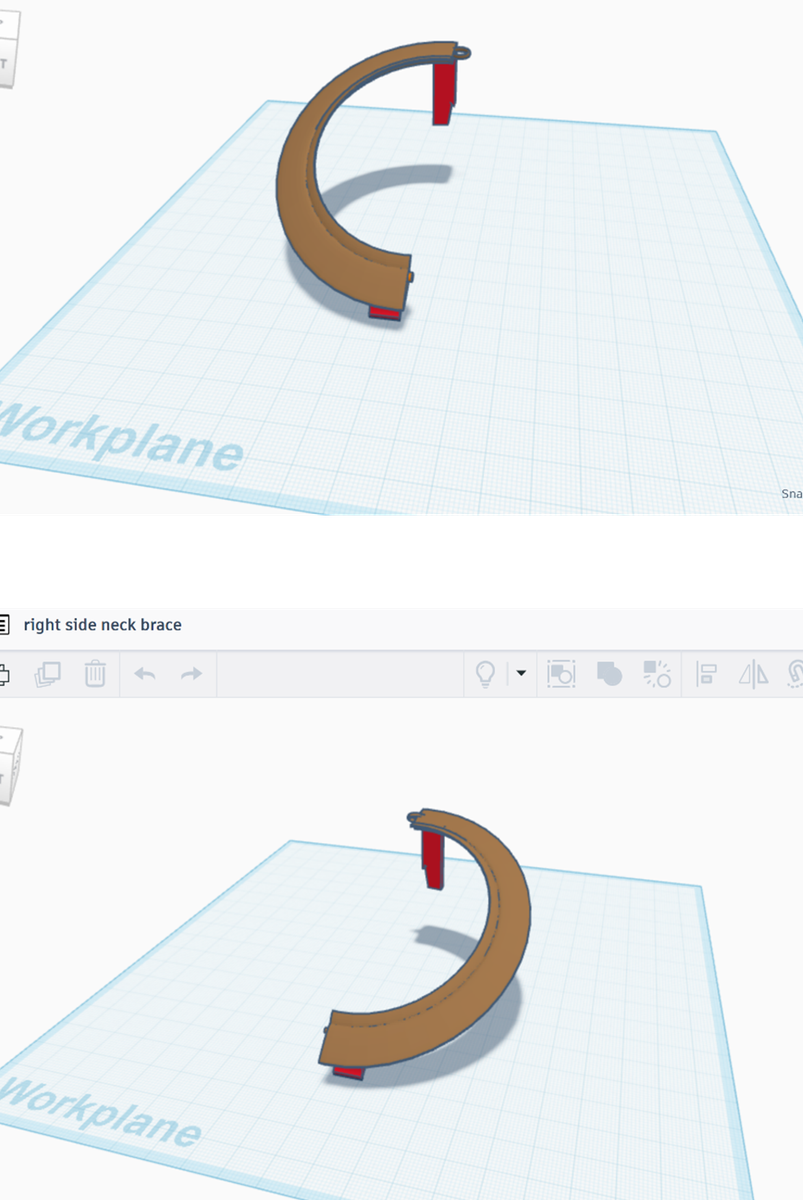

Our Year 8 Innovators have combined creativity, engineering, and problem-solving to design and 3D-print custom medical braces and casts. Working in Tinkercad and Bambu Lab, each student researched, modelled, and printed their own unique design to fit a real-world need.

Finger Brace for Sports Injuries: Harmony Lawrence created a dual-finger brace to help prevent and heal netball injuries. Her design features breathable ventilation holes and precise measurements for comfort and support

“The major challenge of this project was having to reprint the cast, as there were measurement issues and an undesired chunk that was generated when repairing the non-manifold edges of the model. Despite this issue once the cast was re-printed with minor adjustments it returned a great final result" Precious reflected.

Students learned to:

Alongside technical skills, they developed resilience, refining designs, troubleshooting printer settings, and even repairing delicate hinge mechanisms.

“To reach the right size and functionality. My design although partially complex wasn’t exactly creative but taught me a lot about 3d printing and the process of failure within projects and how that’s okay as long as you keep trying and as Mr. K said, “Nothing is perfect follow the 80-20 rule”. Overall, my design was functional and with further improvement to structure, shape and modelling it could be a proper and useful brace within the real world, these designs will fuel and inspire future designs within stem and innovators, and life as we grow older" Abby mentioned in her report.

This project showcases how digital design and additive manufacturing can create personalised medical solutions, while building students’ STEM capabilities in design thinking, engineering, and advanced software.

“My biggest success was learning new skills and overcoming printing issues to create a functional brace,” Evie reflected

Congratulations to all our Year 8 Innovators for their creativity, perseverance, and engineering excellence!