Science & Technology

SYSTEMS ENGINEERING UNIT 3 & 4 PROJECTS

As part of their Unit 3 & 4 Systems Engineering studies, students at St John's Regional College undertook major projects that combined creativity, problem-solving, and technical expertise. Each student was challenged to design, construct, and test a functional system that addressed a real-world problem. From drones and surveillance aircraft to automated CNC machines, these projects showcase the students’ ability to integrate mechanical and electronic systems, demonstrating innovation, persistence, and a profound understanding of engineering principles.

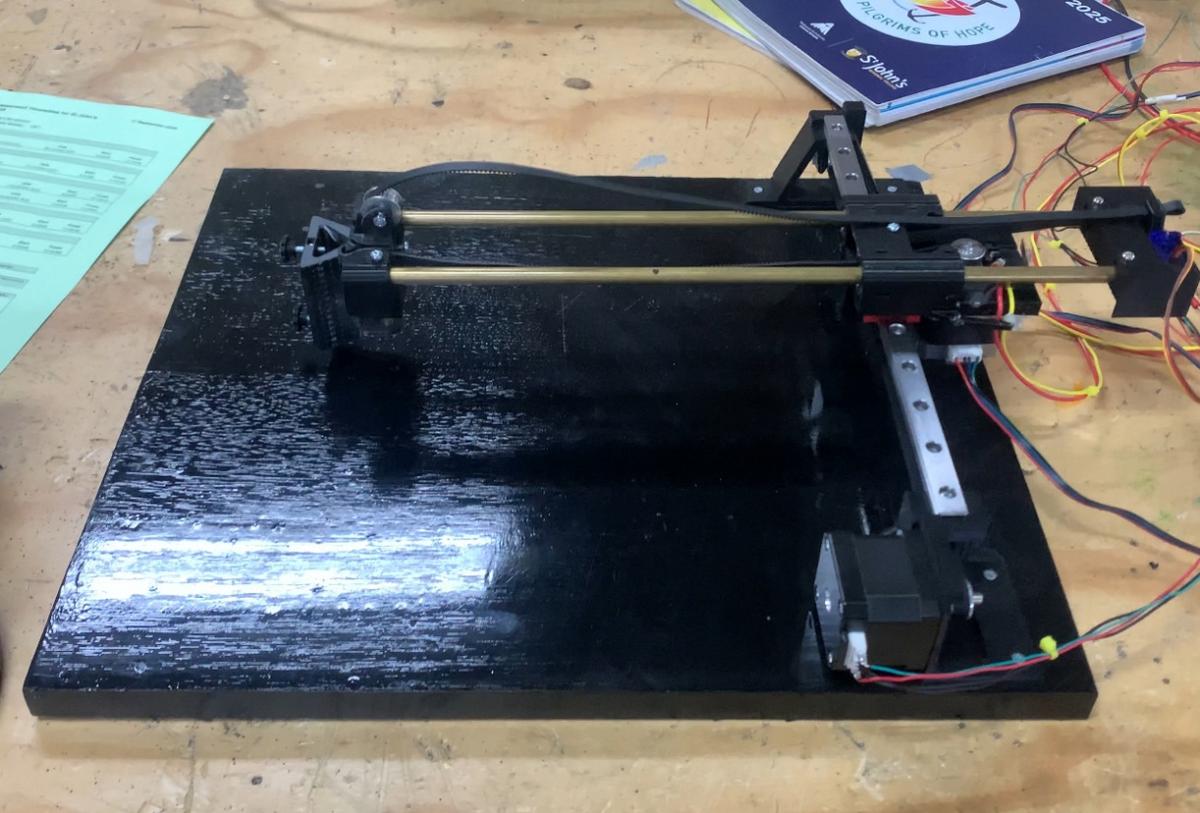

JacobG "The machine is a do-it-yourself CNC drawing or plotting machine that generates automated drawings by combining electronic and mechanical components. Its frame is built from lightweight materials such as wood, with several 3D-printed parts used for mounts, brackets, and the pen holder. To precisely control both horizontal and vertical movement, stepper motors are fastened to the structure and connected to belts and pulleys. These motors drive the X and Y axes. The pen is raised and lowered by a separate Z-axis mechanism, which frequently makes use of a tiny servo motor, allowing it to move without making any marks or draw on the paper. The movement is smoothly guided by linear rods and bearings, and precise positioning is guaranteed by lead screws or belt systems.

An Arduino board, a CNC shield, and stepper motor drivers (like the A4988 or DRV8825) make up the electronic system. The drivers send precise signals to control the motors. Limit switches are frequently included to enable the machine to precisely home itself, and a power supply supplies the current required for the entire setup. After being powered on and linked to a computer, the Arduino running GRBL firmware decodes digital G-Code commands and synchronises all three axes of movement.

The end result is a machine that uses synchronised mechanical and electronic systems to automatically create precise and detailed drawings, transforming digital designs into tangible artwork."

Bass O "In Systems Engineering, we were required to construct a project designed to solve a real-world problem.

I decided to design a low-cost fixed-wing aircraft that could be used in various applications such as surveillance and cargo transport. The aircraft was constructed out of foamboard and electronics commonly used in RC vehicles.

The design was unconventional, with the motor located in the rear and using a "V-tail" rather than a vertical one. The aircraft successfully flew in September, and subsequent flights resulting in a success for the project."

Luis C "For my Systems Engineering project, I designed, built, and tested a low cost shark surveillance drone to help lifeguards monitor beaches safely and efficiently.

The drone was constructed using four Samguk Series Shu 2306 2500KV brushless motors, 5 inch propellers, a 45A ESC, an Omnibus F4 V3S flight controller, a GAONENG 1300mAh 4S LiPo battery, a FlySky receiver and radio controller, and jumper wires for electrical connections. The top plate and frame were 3D printed, joined with Araldite epoxy glue, and reinforced using clamps during curing. Tools such as wire cutters, wire strippers, a soldering iron, a flux pen, and a small file were used throughout assembly to ensure precise connections and clean finishes. I initially tested motor control using a simple Arduino Uno setup with a breadboard, diode, resistor, and transistor before assembling the full drone system with the Omnibus F4 V3S flight controller.

Using Betaflight software, I calibrated the accelerometer, configured motor directions, and bound the controller to the receiver. Despite challenges like oxidized solder pads, frame fragility, and shipping delays for the camera, I achieved stable flight and completed successful diagnostic testing.

The project demonstrated effective use of materials and components, practical problem solving, and careful project management to deliver a functional, affordable surveillance drone prototype."

Nathan B "The finished RC surveillance plane brings together every part of the design into a single, well-functioning system. Powered by a 1400 KV brushless motor and an 8×6 propeller, the aircraft produces steady thrust and efficient performance in flight. The control system uses four micro servos that move the elevator, rudder, and ailerons, allowing smooth and stable manoeuvres across all axes.

A four-channel transmitter and receiver system provide accurate and responsive control from the ground, while the 11.1V 1300 Mah LiPo battery supplies enough power for flights lasting around eight to ten minutes. The airframe, made from lightweight foamboard with carbon fibre reinforcement, keeps the aircraft strong without adding unnecessary weight, helping it achieve good lift and endurance. The onboard surveillance camera, mounted with vibration isolation, records clear and stable video during flight. On the ground, the two-wheel main gear and Perspex tail skid make launching and landing reliable and low-friction.

Overall, the final model performs consistently and demonstrates how the Systems Engineering Process helped turn individual components into a balanced, efficient, and capable surveillance aircraft."

Christopher S "Over the year, I designed and built a fully functional delivery drone as part of my VCE Unit 3/4 Systems Engineering project. Motivated by real-world systems such as Google Wing and Zipline, my goal was to develop an affordable quadrotor that could carry small payloads in difficult environments.

An F4 flight controller, 1700KV brushless motors, and a 6S LiPo battery were among the mechanical and electronic subsystems that required system integration, component testing, CAD modelling, and research. After overcoming several obstacles, such as software calibration issues, shipping delays, and payload balancing challenges, I eventually produced a stable and safe flight prototype.

Despite the payload system's incomplete integration, the drone successfully demonstrated proof of concept for an affordable humanitarian delivery solution throughout the year, showcasing ingenuity, tenacity, and practical problem-solving."