The Green Page:

The Weirdest Ways Scientists Are Mining For Critical Minerals, From Water To Weeds

Not all critical minerals need to come from digging up the earth.

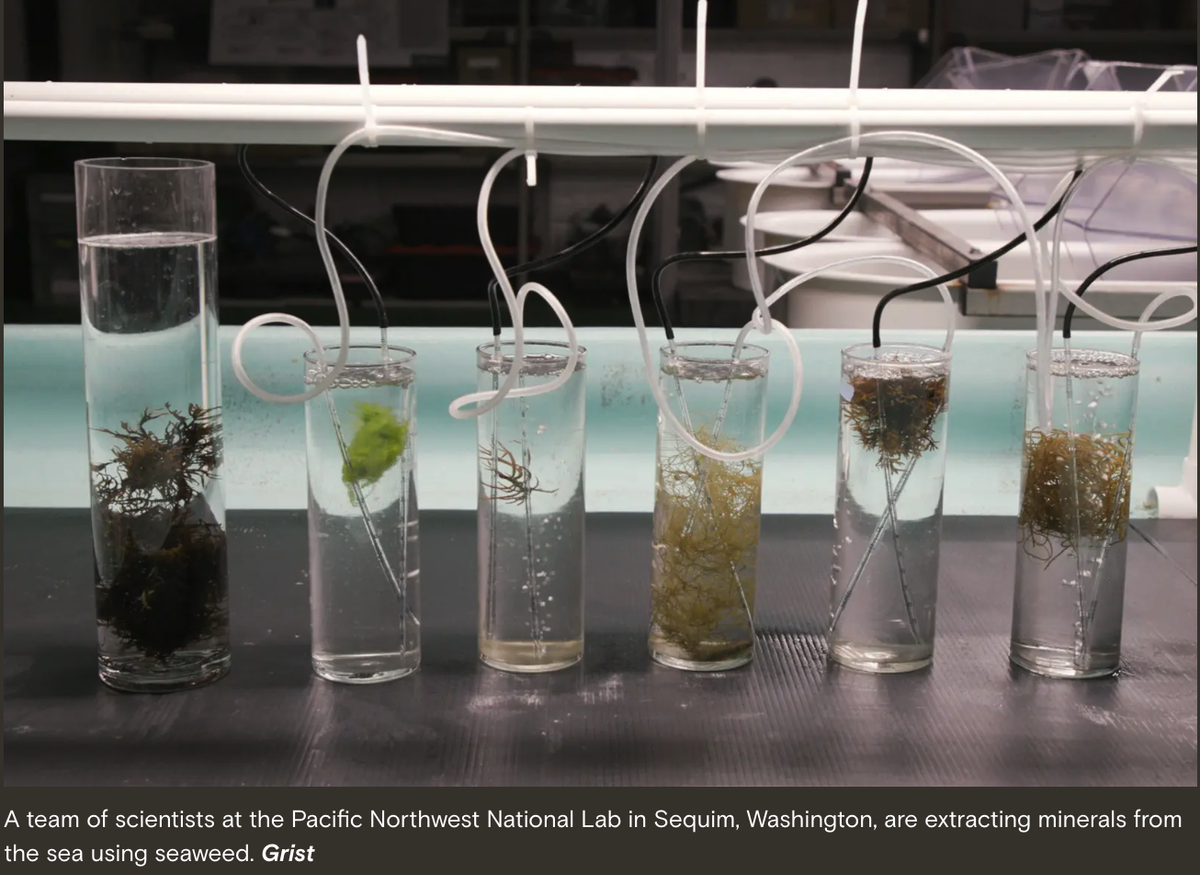

For years, the lab had been studying algae — the broad class of photosynthetic organisms that include phytoplankton, seaweed, and kelp — for a completely different reason: as a potential source for renewable biofuels. The lab would grow algae in tanks and then extract all its organic compounds to use as fuel. This process left behind a concentrated, powdery waste product, rich in all the remaining minerals that weren’t needed for the fuel. At first, researchers didn’t realise the potential of this overlooked byproduct. Scott Edmundson, a research scientist at the lab, recalls when he realised, “Oh, there’s a lot of minerals here that we really are undervaluing.”

As part of a Department of Energy experimental research program, they developed a system to pump seawater into onshore grow tanks full of a type of mineral-loving seaweed called Ulva. From there, they harvested and dried the seaweed, then processed it into the mineral-rich powder, which they dubbed “bio-ore.” This powder contains precious elements, such as nickel, cobalt, and rare earths, at levels thousands of times higher than those found in seawater. For example, concentrations of the rare earth element neodymium — an essential component in wind turbines — can be up to 479,000 times higher than the original seawater.

The dream of extracting gold, cobalt, and many other critical minerals from seawater remains far from being commercially feasible. However, scientists like Edmundson — and others, such as Cornell University scientist Maha Haji, who has designed mineral filters that could be hung from abandoned oil rigs to extract cobalt from the Gulf of Mexico — believe that seawater mining has the potential to reshape how the world sources its minerals fundamentally.

“If you can make that work, and you can do it in a way that’s environmentally responsible, that has such high potential for providing the minerals we need in a sustainable, egalitarian way,” Edmundson said. “If you have access to the ocean, you have access to the minerals.”

Mining our weeds

Each spring, Albania’s mountainous roads are suddenly lined by striking yellow weeds with oblong leaves and tiny blossoms. A relative of broccoli, cabbage, and wild mustard, Odontarrhena chalcidicais expertly adapted to the rocky soils of this Balkan country, which are unsuitable for most other kinds of vegetation because of their high nickel content. O. chalcidica has developed the ability not only to survive in this environment, but also to utilise its toxicity to its advantage. The plant draws nickel up from the soil and stores it in its leaves and stems, which botanists believe serves as a defence against predators and diseases.

But this defensive maneuver could also make this unremarkable-looking weed a critical tool for the clean energy transition. For years, scientists have known that plants like O. chalcidica, known as hyperaccumulators, can be harvested and burned to extract the nickel contained within their cells. This is called phytomining. Now, companies are starting to catch on, working to apply phytomining on a scale that could actually put a dent in global demand for nickel, which is used in solar panels, wind turbines, and the lithium-ion batteries that power electric vehicles.

One of these is Metalplant, a startup founded four years ago by three American and Albanian entrepreneurs. Metalplant worked with researchers at Albania’s Agricultural University of Tirana to transform O. chalcidicafrom a simple weed into a valuable crop. The company estimates that the plant can produce between 440 and 880 pounds of nickel per hectare in one growing season. Theoretically, this means that the entire global nickel demand in 2020 could be met by cultivating O. chalcidica on approximately 23,000 square miles, an area slightly smaller than the state of West Virginia. Although Metalplant hasn’t yet revealed its buyers, the company harvested its second batch of O. chalcidica last June, containing a few hundred pounds of the precious metal nickel.

Eric Matzner, one of Metalplant’s three co-founders, does not believe that supplanting the entire global nickel supply chain is a realistic near-term goal. But he imagines that his company can provide a cleaner source of nickel — one that doesn’t cause the kind of deforestation, air and water pollution, and seizure of Indigenous lands seen in Indonesia, the world’s largest producer of the metal. Though traditional nickel mines currently have a cost advantage due to their sheer scale, Metalplant aims to become competitive by providing an additional service: carbon dioxide removal. The company is using a technique known as enhanced rock weathering, which involves spreading crushed rocks containing silicate minerals on O. chalcidica fields as they grow. This rock debris not only boosts yields by replenishing nickel in the soil, but it also reacts with carbon dioxide in the air to lock away the greenhouse gas as a solid, which is later washed away by rain and ultimately deposited in the ocean.

The result, which the company calls “carbon-negative” nickel, can be purchased by carmakers aiming to offset their own carbon emissions. In theory, this could enable an electric vehicle to claim carbon neutrality for its entire life cycle. And it’s not just carmakers who are interested: Researchers at the University of Lorraine in Nancy, France, recently formed a partnership with steelmaker Aperam to use phytomined nickel in stainless steel production. In March of last year, the U.S. Department of Energy announced that it would fund research into phytomining, aiming to enhance the process's efficiency and scale, with the ultimate goal of bolstering the domestic supply chain for nickel and reducing imports. (ARPA-E, the program that distributes the funding, has been targeted by the Trump administration, and its future role in supporting phytomining research is unclear.)

Companies like Metalplant have a long way to go before they can draw buyers away from established nickel producers in Indonesia. However, Albania has a few other advantages: its mountains are rich in olivine, a rock that is ideal for ERW, and its numerous hydropower dams provide ample renewable energy needed to crush those rocks so they can be spread and sequester carbon dioxide. Albanian farmers are struggling with poor harvests and an exodus of young people to cities and abroad, which means they welcome the chance to explore new economic opportunities, according to Matzner. The way he sees it, “We’re literally growing money on trees.”