Cranes and Hoists

While working with or near cranes and hoists we are more exposed to serious hazards. Your full attention must apply when working in this type of work environment, there are no second chances.

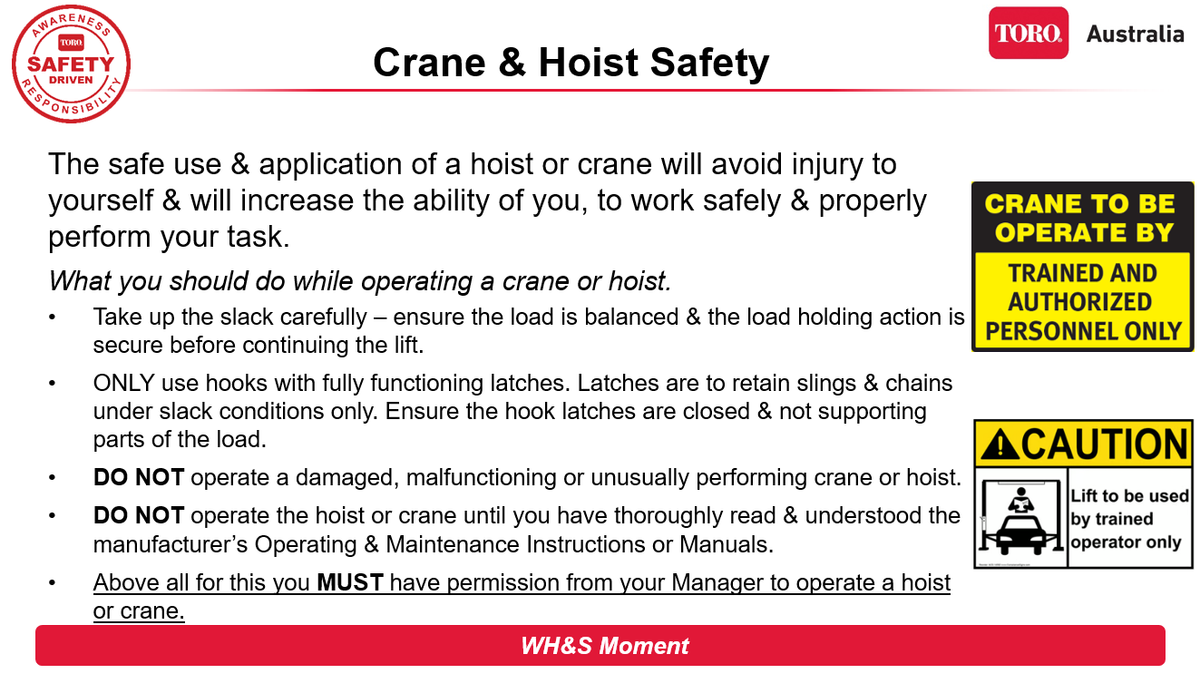

Safe operation of all Toro Australia cranes and hoists are extremely important in all our Service and Manufacturing areas.

- A significant part of this involves regular daily inhouse hoist and crane logbook inspections by the first person to use the hoist or crane on any given day.

- This also means for cranes:

- inspecting the hooks (and spring latch), bow shackles, synthetic slings, chains (their hooks and links), and any other signs of wear or distortion.

- For hoists:

- Safety locking systems can be heard when raising, vehicle support pads, footings, oil level, oil leaks, any deformation

- This also means for cranes:

- It is a legal requirement by all WorkSafe authorities across the country to have 12 monthly third-party inspection carried out.

Within the Service and Manufacturing space, a crane and hoist management strategy is a critical puzzle piece for our facilities to look after one another.

- This will ensure our crane and hoist equipment – and those managing the machinery – operate it as efficiently and safely as possible.

- By prioritising a proficient crane and hoist management system, we have safe equipment to always use, we maximize our machinery investment and not just in throughput, but in reducing equipment breakdown times.