Product Design & Technology

VCE-Product Design and Technologies

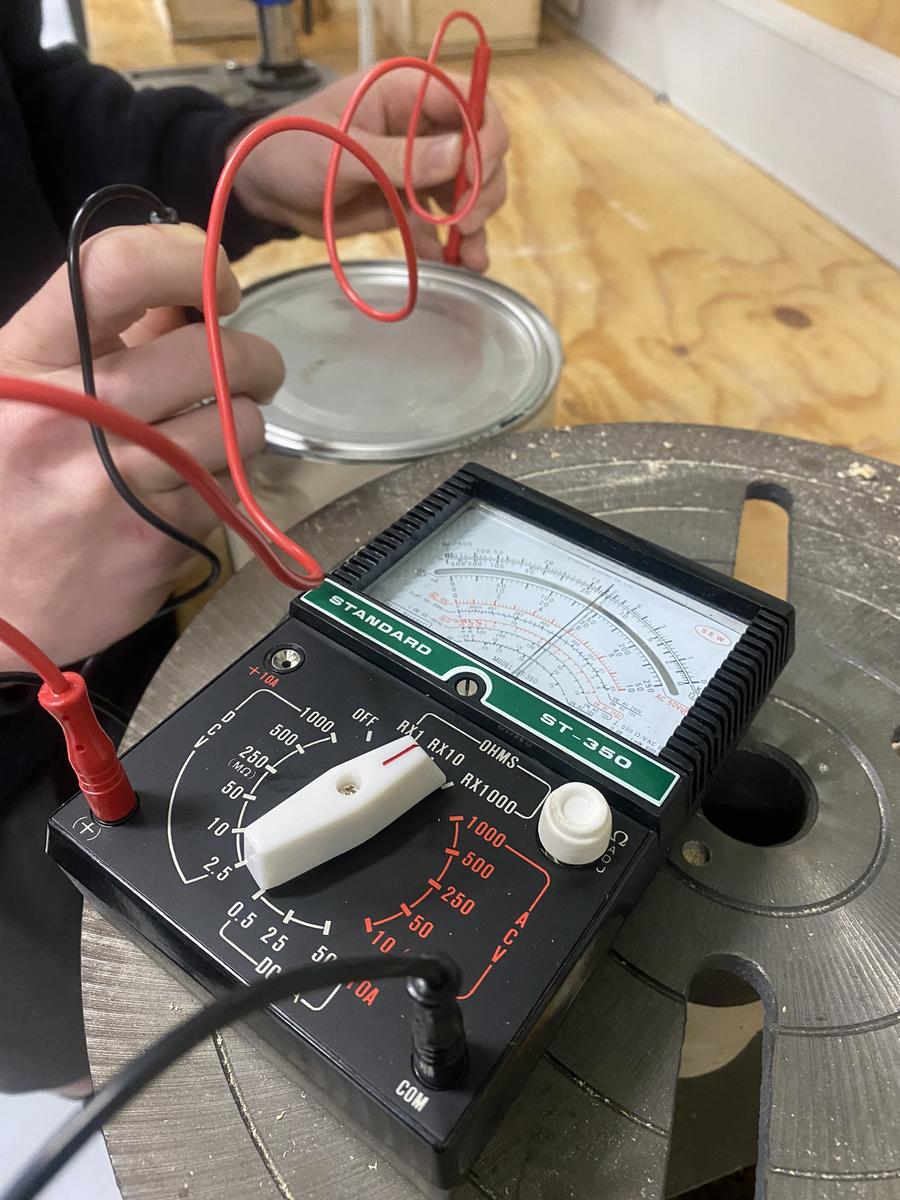

Resistant materials are predominately wood, metal, fabric and plastic and our Product Design and Technologies students have started testing characteristics and properties. A great deal of fun was had with weights, clamps, shotput balls and thermometer tools.

Elasticity is the ability of a material to return to it’s original shape and straightness after a heavy, deforming load is removed. We had gym weights hanging on the different masonite, pine, plywood and chipboard samples. The plywood instantly snapped after 1 kilo was loaded, whereas the meranti bent but then sprang back.

Toughness is the ability of these materials to absorb energy upon impact, and not be deformed. When a 1 kilo shotput was dropped on each of the materials from a predetermined height there were varying outcomes. Melamine received a small 11mm dent, pine received a 25mm dent and acrylic sent out a large star shaped shatter.

Thermal conductivity is the ability of a material to transmit heat. We used a thermometer to test for heat being transferred in a material. Needless to say that most metal objects were the highest recordings to note the rise in temperature of the product.

Corrosion refers to the vulnerability of a material to corrode or break down the material due to chemical attack. Think rust, mould and expansion as examples. Currently we have pine, Masonite, plywood, brass, aluminium and stainless steel soaking in baths of salt water, vinegar (acid), bicarb soda (alkaline) and dye baths to see if they mould, rust or simply expand.

Each of these things is simple, in a manner, but also very telling of we could, and what we should, use each material for. In the world of trade and designing these are the characteristics that students need to innately know. Our testing will continue next semester.

Amanda Hard

amanda.hard@smseymour.catholic.edu.au